ABOUT US

Be grateful to meet and serve with heart

Ningbo Sky commodity Commodity, the company was established by Skygroup Team in 2006 Year.

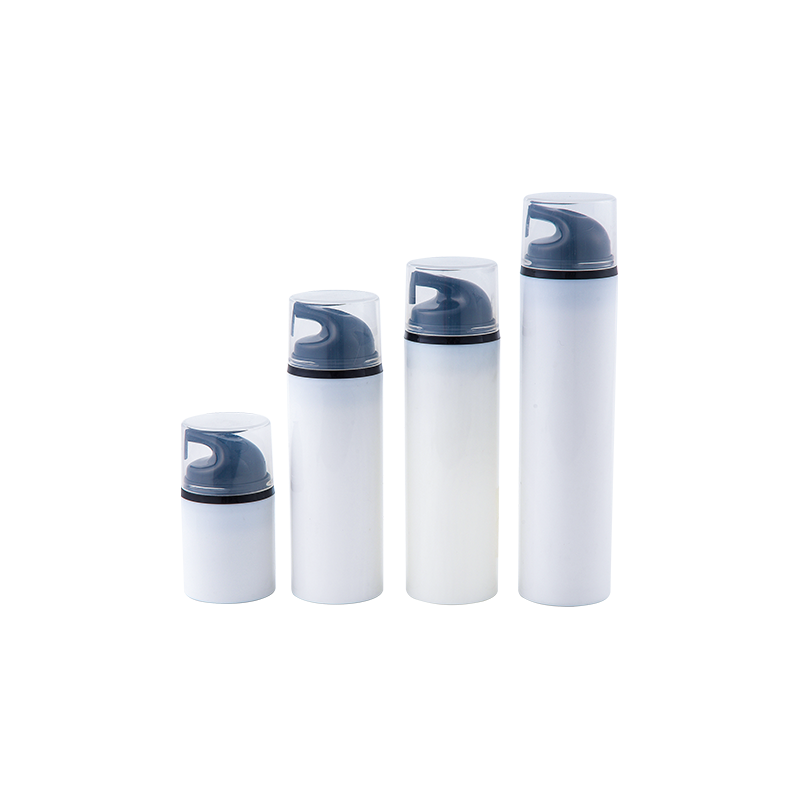

We are a China professional triggerers and sprayers manufacturers and wholesale spray bottle factory.

Our company is close to Ningbo, shanghai port, and our markets are Austria, Spain, USA, UK, Greece, Africa and also China market. SkySprayer is the logo of the company, Sky means Strong, Key, Young. Let’s stronger together is the key to making our life younger. Our company's philosophy is great love and altruism.

VIEW MORE

Español

Español

Français

Français

.png?imageView2/2/format/jp2)

(5).jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

(5).jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)