What is the primary mechanism by which cosmetic airless bottles help prolong the shelf life of cosmetics?

The primary mechanism by which

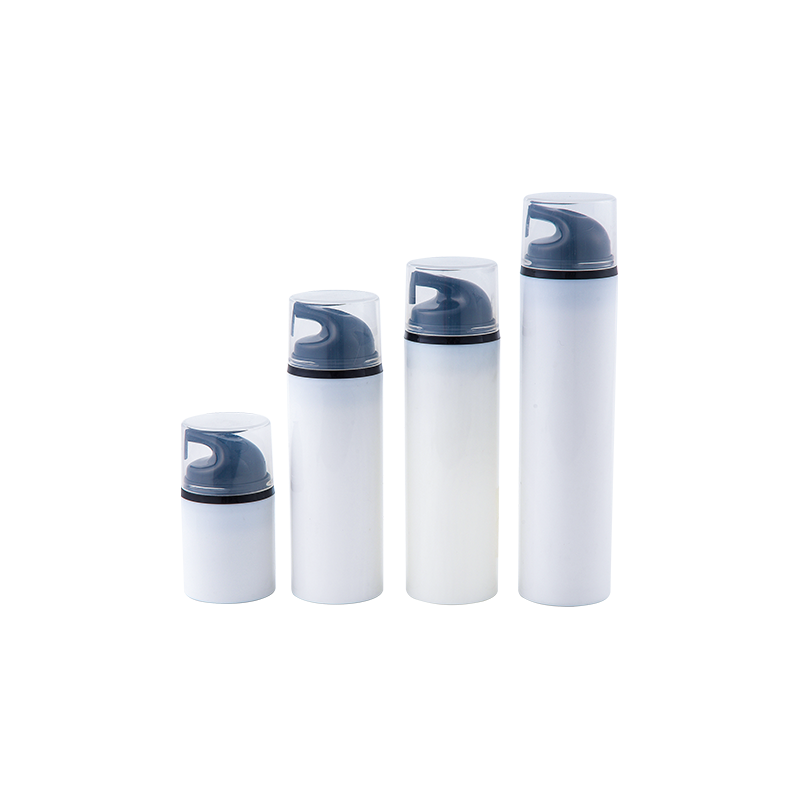

cosmetic airless bottles help prolong the shelf life of cosmetics is through their airless dispensing system. This system relies on a vacuum or piston mechanism to create a controlled and air-free environment within the bottle, which offers several benefits:

Air-Tight Seal: Cosmetic airless bottles are designed with a vacuum pump or piston at the bottom. When the pump is pressed, it creates a vacuum that draws the product up without letting air enter the container.

Preventing Oxidation: Oxygen exposure is one of the main causes of cosmetic product deterioration. By eliminating contact with air, airless bottles significantly reduce the risk of oxidation. This is particularly important for products like serums and creams that contain active ingredients sensitive to air.

Minimizing Contamination: The airless system prevents the product from being exposed to contaminants present in the external environment, such as dust, dirt, and bacteria. This minimizes the risk of microbial growth and maintains product safety.

Hygienic Dispensing: The product is dispensed without direct contact with the user's fingers or the surrounding environment, ensuring a hygienic application every time.

Preserving Product Freshness: Cosmetic airless bottles allow for efficient evacuation of the product, ensuring that there is minimal product residue left in the container. This means that the last dose is as fresh and uncontaminated as the first use.

Reducing Product Waste: Traditional packaging, like jars or bottles with open tops, can lead to product waste as the product comes into contact with air and contaminants. Airless packaging reduces this waste, saving both product and money.

Longer Shelf Life: The combination of reduced air exposure, contamination, and product waste translates to a longer shelf life for the cosmetic product stored in airless bottles.

Precise Dosage: Airless bottles are designed to provide precise and controlled product dispensing, reducing the risk of overuse and product waste.

Overall, the airless dispensing system is the primary mechanism by which cosmetic airless bottles help extend the shelf life of cosmetics. This innovative design plays a significant role in preserving the quality and safety of cosmetic products, particularly those with sensitive formulations or active ingredients.

How do cosmetic airless bottles prevent the entry of air into the container when dispensing the product?

Cosmetic airless bottles are designed to prevent the entry of air into the container when dispensing the product. This is achieved through the use of an airless dispensing system, which relies on a vacuum or piston mechanism. Here's how cosmetic airless bottles work to maintain an air-free environment:

Vacuum or Piston Pump: Cosmetic airless bottles are equipped with a vacuum or piston pump that is typically located at the bottom of the container. This pump is responsible for creating a vacuum or negative pressure within the bottle.

Airtight Seal: The pump is fitted with a one-way valve or diaphragm that opens when pressure is applied and closes when pressure is released. This valve creates an airtight seal when not in use, preventing external air from entering the container.

Product Chamber: The cosmetic product is stored in a separate chamber within the bottle. This chamber is typically made of a flexible material that can collapse as the product is dispensed, allowing the vacuum pump to maintain pressure.

Dispensing Process: When you press the pump, it depresses, creating a vacuum within the product chamber. This vacuum draws the flexible chamber inwards, forcing the product out through the dispenser. The one-way valve at the bottom of the pump remains closed, preventing air from entering the chamber.

Precise and Controlled Dispensing: The vacuum created during the dispensing process ensures that the product is pushed out without allowing air to enter. This results in precise and controlled dispensing of the product, minimizing waste and maintaining product integrity.

No Contact with Fingers: With airless bottles, the product is dispensed without direct contact with the user's fingers, further reducing the risk of contamination. This is particularly important for products that are sensitive to air and external contaminants.

Consistency Over Time: Throughout the life of the product, the airless system consistently maintains an air-free and contamination-free environment. This helps preserve the product's quality and extends its shelf life.

By using this airless dispensing system, cosmetic airless bottles effectively prevent the entry of air into the container during product dispensing, which is essential for maintaining the freshness, safety, and longevity of cosmetic products.

Español

Español

Français

Français

.png?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)