What is the primary function of the trigger mechanism in a

fine mist trigger, and how does it initiate the spray process?

The primary function of the trigger mechanism in a fine mist trigger is to initiate the spray process by creating pressure within the sprayer and controlling the release of the liquid. Here's how it works:

Pressure Generation: When you squeeze or pull the trigger, it activates a pump or piston mechanism within the sprayer. This action generates internal pressure by compressing air or other fluid in the sprayer's chamber. The pressure buildup is essential for forcing the liquid out of the container.

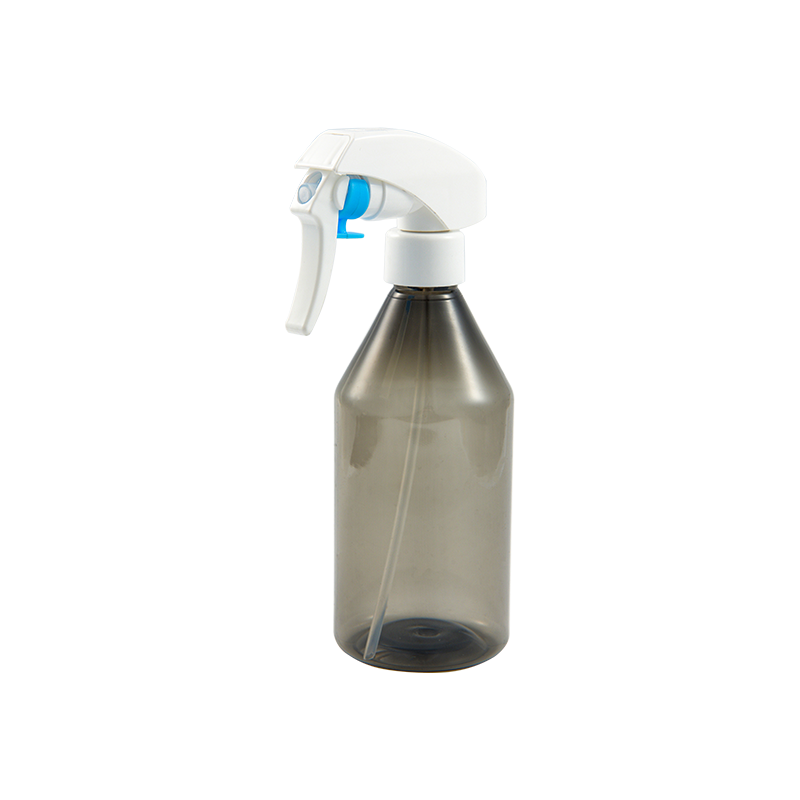

Liquid Flow: The trigger mechanism is connected to a dip tube that extends into the liquid product inside the container. When pressure is generated, it pushes on the liquid, forcing it to flow up the dip tube and into the sprayer's internal chamber.

Nozzle Activation: Once the liquid is in the sprayer's chamber, the trigger mechanism controls the release of the liquid through the nozzle. This nozzle is specially designed to break the liquid into fine droplets and create a mist spray pattern.

Spray Pattern Control: The trigger's design and operation determine the spray pattern. Squeezing or pulling the trigger controls the amount of liquid released, and the nozzle design ensures that the liquid is atomized into tiny droplets, creating the fine mist spray pattern.

Release and Closure: Releasing the trigger stops the flow of liquid and closes off the nozzle. The pressure inside the sprayer is released, and the liquid flow ceases. This action prevents leaks and allows for controlled and precise application.

The trigger mechanism, therefore, plays a crucial role in the precise and controlled dispensing of the liquid product, resulting in a fine mist spray pattern. It allows users to apply the product evenly and efficiently in various applications, such as personal care, cosmetics, household cleaning, and more.

How does the trigger mechanism create pressure within the sprayer to force the liquid through the nozzle?

The trigger mechanism in a sprayer creates pressure within the device to force the liquid through the nozzle. This process typically involves a pump or piston mechanism. Here's how the trigger mechanism generates pressure:

Squeezing or Pulling the Trigger: When you squeeze or pull the trigger of the sprayer, it activates the pump or piston mechanism. The trigger is connected to this mechanism, which is responsible for generating pressure.

Piston or Pump Movement: The pump or piston is a component within the sprayer that can move within a cylinder or chamber. When you squeeze or pull the trigger, it initiates the movement of the piston or pump.

Compression of Air or Fluid: As the piston or pump moves, it compresses either air or another fluid (often water) within the cylinder or chamber. This compression creates an increase in pressure within the sprayer.

Pressure Buildup: The compression of air or fluid results in pressure buildup within the sprayer. This pressure is what forces the liquid product to move from the container, up the dip tube, and into the internal chamber of the sprayer.

Liquid Flow: With the pressure built up, the liquid is pushed out of the container and into the sprayer's internal chamber. The pressure ensures a steady and controlled flow of the liquid.

Nozzle Activation: The nozzle at the front of the sprayer is designed to disperse the liquid in the desired spray pattern. The pressure forces the liquid through the nozzle's small orifice, where it is broken into fine droplets, creating the mist or spray pattern.

Release and Closure: When you release the trigger, the pump or piston mechanism returns to its original position, releasing the pressure. The liquid flow is stopped, and the nozzle is closed to prevent further discharge.

By manipulating the trigger, users can control the pressure and, consequently, the flow of the liquid product. This mechanism allows for efficient and controlled dispensing, enabling the creation of a fine mist spray pattern for various applications.

Español

Español

Français

Français