What are the environmental considerations of using PET material in cosmetics packaging, especially in comparison to other materials like glass or biodegradable options?

When evaluating the environmental considerations of using

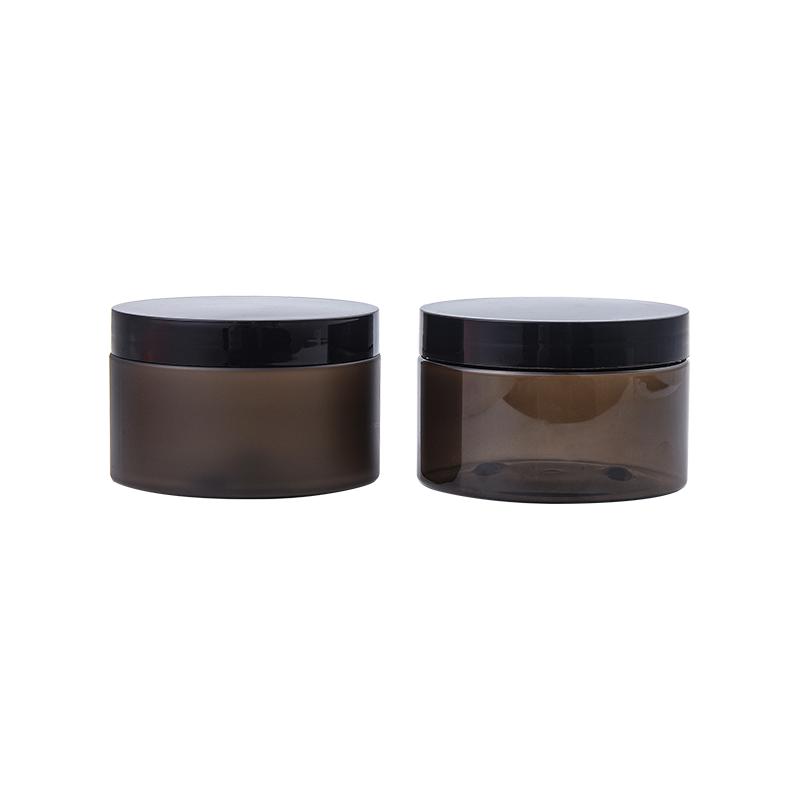

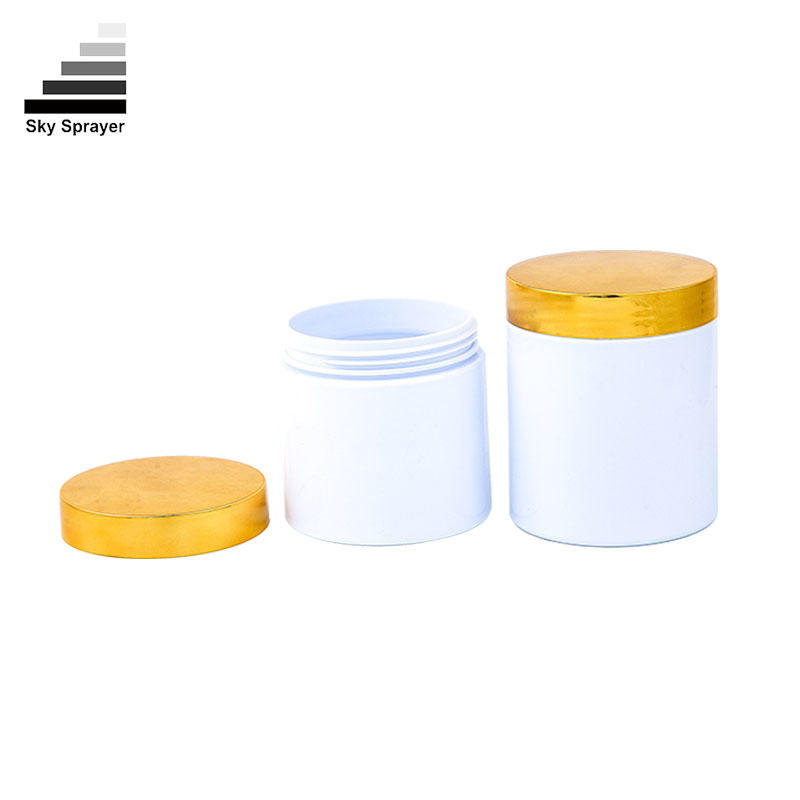

PET material cosmetic jars in cosmetics packaging in comparison to other materials like glass or biodegradable options, several factors should be taken into account:

Recyclability: PET is highly recyclable. It can be recycled and reprocessed into new products, including more PET containers. This reduces the need for virgin plastic production and helps lower the carbon footprint. Glass, while also recyclable, is heavier and more energy-intensive to produce and transport, making it less environmentally friendly in terms of carbon emissions.

Energy Consumption: PET typically requires less energy to produce than glass. Glass production involves high-temperature processes, which can be energy-intensive. In contrast, PET manufacturing is generally more energy-efficient.

Transportation Costs: PET is lighter than glass, which reduces transportation costs and associated carbon emissions. This aspect is especially important when considering the environmental impact of shipping cosmetic products.

Biodegradability: While PET is not biodegradable and can persist in the environment for a long time, it is not the only material with this characteristic. Many biodegradable materials, like some bioplastics, have limitations and may not break down as expected in all environments. Therefore, the actual environmental benefits of biodegradable options can vary depending on disposal methods and local conditions.

Landfill Impact: Both PET and glass do not biodegrade in landfills, so neither is an ideal option in this regard. Biodegradable materials, if properly managed, can decompose more quickly in landfill conditions.

Resource Extraction: PET is derived from petroleum, which is a non-renewable resource. In contrast, glass is made from abundant raw materials like sand, soda ash, and limestone. Biodegradable materials may be made from renewable sources, but the environmental impact also depends on the agricultural practices used for their cultivation.

Carbon Emissions: PET generally has a lower carbon footprint compared to glass due to its lower weight and energy-efficient production. Biodegradable options may vary widely in terms of carbon emissions, depending on the source and production methods.

Waste Management: The ease of recycling PET can lead to more effective waste management when compared to glass. However, biodegradable materials may require specific composting facilities to decompose properly, and their environmental benefit depends on proper disposal methods.

Lifecycle Assessment: A comprehensive analysis of the complete lifecycle of each material is necessary to determine its overall environmental impact, including extraction, production, transportation, usage, and end-of-life considerations.

In conclusion, while PET is not biodegradable, it can offer environmental benefits in terms of lower energy consumption, reduced transportation costs, and efficient recycling. The choice between PET, glass, or biodegradable materials for cosmetics packaging should be made based on a thorough assessment of specific environmental factors and local recycling infrastructure. Additionally, ongoing efforts to reduce plastic waste, increase recycling rates, and develop sustainable packaging materials should be considered in the context of the cosmetics industry's environmental impact.

Español

Español

Français

Français